Published in "CHINESE JOURNAL OF LASERS" | 150 kW Ultra-High Power Fiber Laser

Fiber lasers, as a mainstream direction in the development of laser technology, boast excellent performance, high electro-optical conversion efficiency, good beam quality, and stable performance. They have been widely used in industrial processing, aerospace, defense, and medical fields. Driven by the robust market demand for laser processing, the power of industrial-grade ten-kilowatt fiber lasers has been continuously breaking upper limits, achieving a 120 kW laser output in 2017. However, due to bottlenecks in laser thermal management, nonlinear effects, and ultra-high power laser measurement technology, there has been no new breakthrough in the output power of ultra-high power fiber lasers.

BWT Beijing Ltd. (hereinafter referred to as "BWT") has achieved a breakthrough in the manufacturing process of high-power laser beam combining and output core optical components by studying efficient heat dissipation technology and high beam quality beam combining technology for fiber lasers, constructing a high-performance optical platform, and realizing high beam quality laser output of 150 kW ultra-high power fiber lasers. Meanwhile, BWT's researchers have built an ultra-high power measurement platform based on the principle of optical pressure. Certified by the National Institute of Metrology, China, this platform can achieve full power laser measurement of 150 kW.

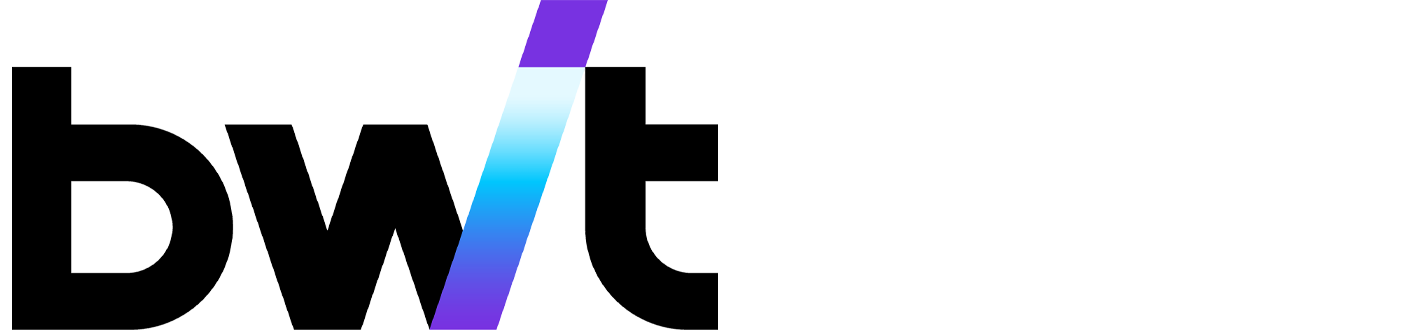

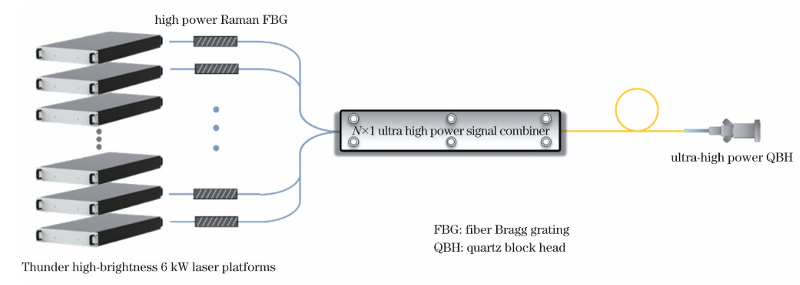

The BWT 150 kW industrial-grade ultra-high power fiber laser adopts ultra-high power beam combining technology, using an N×1 signal combiner to synthesize the power of multiple highly integrated 6 kW optical platforms based on chip integration technology. Combined with multi-information fusion laser intelligent monitoring technology, it achieves stable laser output and features an industry-leading power-to-volume ratio (36.76 kW/m³). Its external dimensions are 1800 mm × 1300 mm × 1745 mm. As shown in Figure 1, each optical platform integrates self-made high-power Raman gratings, which efficiently suppress the stimulated Raman scattering of the laser spectrum. After full power synthesis, it can achieve a Raman signal-to-noise ratio of 36.5 dB@150 kW, as shown in the left image of Figure 2. The high-power signal combiner is made using adiabatic tapering and lossless fusion technologies, which solve industry pain points such as low beam combining efficiency and beam quality degradation. The beam combining efficiency of the signal combiner is 97.1%. Additionally, the integrated water-cooling technology solves the heating problem of the optical module, signal combiner, and high-power output head. The high-power output head uses a 200 μm core diameter output fiber, 20 m in length, and employs beam divergence angle compression and higher-order mode filtering technologies to achieve high power, high brightness laser output. The beam quality of the entire machine was tested, and the quality factor M²=24.42 (beam parameter product BPP of 8.4 mm·mrad). The test results and spot images are shown in the right image of Figure 2.

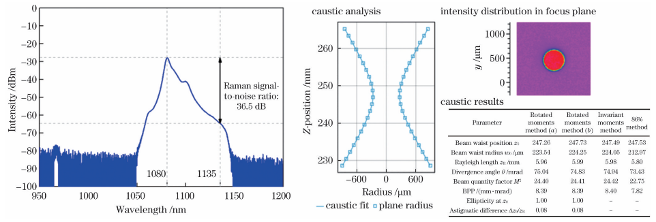

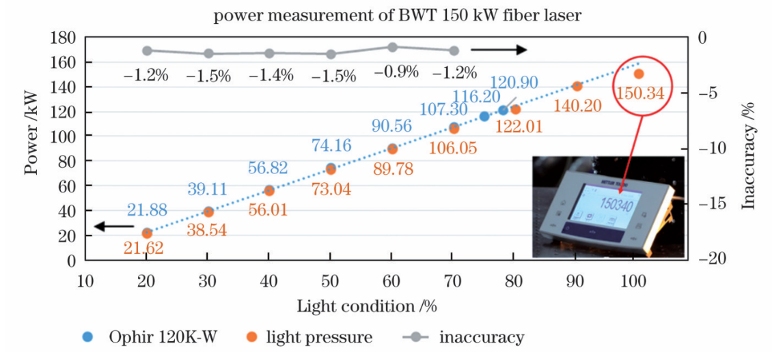

To achieve accurate measurement of the 150 kW laser, an ultra-high power optical pressure measurement system was built. This system consists of the laser to be measured, a high-power collimator head, an optical pressure power meter, and a high-power laser collection system. The collimated laser is output from the output window after three reflections in the power meter and collected by a self-made ultra-high power laser collection system, as shown in Figure 3. Under 100% output conditions, the measured power of the laser is 150.34 kW, as shown in Figure 4. In the power range of 20-100 kW, a comparative verification experiment was conducted with six power points between the calorimetric 120 kW power meter (Ophir 120K-W) and the optical pressure power meter. The results showed that the power deviation between the two measurement methods remained relatively consistent in all power segments, with the maximum relative deviation ≤1.5%, proving the accuracy and reliability of the testing system.

In summary, this fiber laser can achieve an average power output of 150 kW with a Raman signal-to-noise ratio of 36.5 dB and a beam quality factor of M²=24.42. It features high power, high brightness, and high stability, meeting the demands for ultra-thick plate processing and injecting new vitality into the development of the manufacturing industry.

Fig.1 Schematic design of 150 kW industrial ultra-high-power fiber laser

Fig.2 Optical spectrum of 150 kW high power fiber laser (left) and beam quality test (b)

Fig.3 Schematic diagram of ultra-high power laser measurement system based on the principle of light pressure

Fig.4 Comparison of measured power between laser measurement system based on the principle of light pressure